Printing Machine MS EVO 320

Product code

: 0000

| Price: |

|

| Printer Type : | Textile |

| Model : | MS-JPK EVO |

| Printing width : | 1000 x 3200 mm |

| Options | Price | Description |

|---|---|---|

| Total cost : |

|

|

Availability

:

в наличии

Warranty

:

12 months of the official warranty from the manufacture.

- Description

- Specifications

- Reviews

- With product is used

- Specification refinement

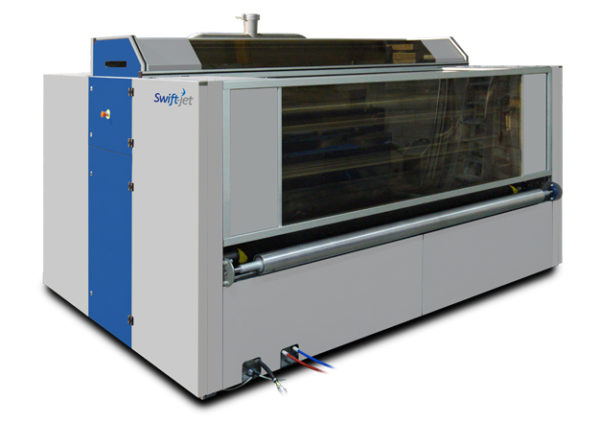

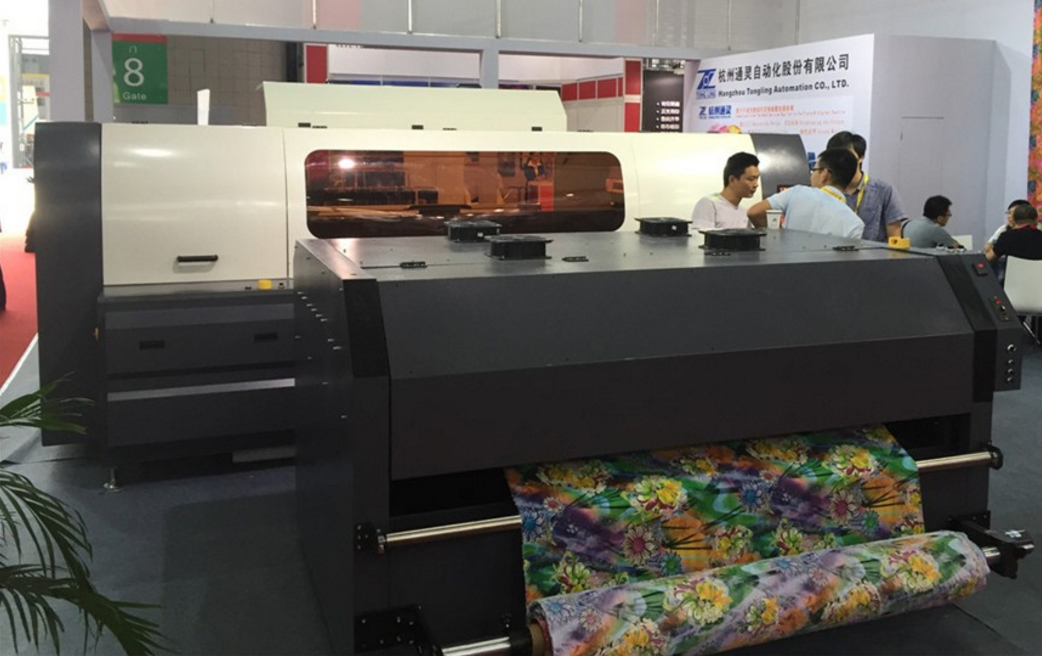

MS Ink-Jet printing machine, mod. MS JPK EVO 320 with the dryer MS - POWERDRY,

working width 3200 mm.

Year of production 2014.

Max. speed (double CMYK)1410 sqm/hInd

production speed (double CMYK)700 sqm/h

Max. speed (8 single colors)1140 sqm/hInd.

production speed (8 single colors)575 sqm/h

Printing resolution Up to 1200 dpi

Graylevels16

Drop SizeFrom 4 to 72pl

Features

- Open ink system

- Open software system

- Embedded remote diagnostic

- Embedded web server for cost report

Printing width Up to 320 cm

Printing head 32

Installed electrical power: 40 kVA

Required water pressure: 2 bar

Water Consumption: approx. 100-400 l/h

Required air pressure: 7 bar

Compressed Air consumption: approx.150 l/min

Electrical Voltage: 400 Volts - 50 Hz - III

Max roll diameter exit: 350 mm

Diameter of cardboard tubes at entry: 2” internal diameter (48-50 mm)

Max roll diameter entry: 400 mm

Number of installed rows: 4

Number of colours: 8

Power-D dryer:

. Installed electrical power: 7 kVA

. Installed heating capacity: 43000 kcal

. Max. air temperature: 120°C

. Compressed air consumption: 0,5 l/m

. Required air pressure: 6 bar

. Number of passages: 3

Unwinding unit

Fabric feeding

Pressure roller

Crease sensors

Printing blanket

Blanket heating

Blanket washing

Print carriage bar

Print carriage

It is equipped with vertical movement both to adjust the distance of the heads from the substrate to be printed, as well as to move it into the rest position (parking ) during the phases of machine downtime and maintenance. Thanks to this movement, it is possible to print media with different thicknesses. Above them also a part of the ink management system is positioned that feeds the heads as well as the electronic control system, both connected to the machine via power track trains.

Kyocera print heads model KJ4.

Fabric detachment sensor

Fabric detachment roller

Dryer

Winder

Blanket drying roller

Resin squeegee

Cleaning tank

Touch screen

Computer housing

Electrical cabin

Ink framework

For a proper function of the technology used in ink jet, it is mandatory to install MS machines in a room with air conditioning. The temperature should be around 25°C and the humidity should range between 60 and 65% with a reduced load of dust. By controlling the air temperature and humidity, the aim is to prevent irreversible print head damages and to keep the correct function of the heads as well as to avoid that a high number of cleaning operations is required. Without the above-mentioned conditions, we do not guarantee the correct function of the inks and other consumable products. Furthermore, inks and consumables must be stored in the same environmental conditions as the machine.

| Printer Type : | Textile |

| Product code : | 0000 |

| Model : | MS-JPK EVO |

| Printing width : | 1000 x 3200 mm |

| Condition of equipment : | new equipment |

| Printing type : | Piezo-jet |

| Feeding system : | Rolling |

| Color chemes : | CMYK + ORGB , CMYK x 2 |

| Printhead from : | Kyocera |

| Print head type : | KJ4B-QA |

| Q-ty printhead : |

32 pc

For each color - 8 pc СМУК - 32 pc |

| Compatible ink : | Sublimation, Textile |

| Drop type : | Variable |

| The size of the drop : | Variable from 4.0 pl before 72.0 pl |

| Print speed : |

Draft Speed: 2 pass 600х600 dpi - 825.0 sq.m./hour.

Fast Speed: 3 pass 600х600 dpi - 750.0 sq.m./hour. Normal Speed: 4 pass 600х600 dpi - 550.0 sq.m./hour. Quality Speed: 6 pass 600х600 dpi - 450.0 sq.m./hour. |

| Printing resolution : | 600x600dpi |

| Maximum carrier thickness : | 1200.0 mm |

| Average power consumption : | 40000 w |

| Maximum power consumption : | 41000 w |

To leave a comment you need to come in the system.

To leave a comment you need to come in the system.